Soldier Pile Walls

Soldier Pile Walls – such an odd name, but it has been with us for centuries.

What are Soldier Pile Walls and how do they work?

The “soldier” portion of the name derives from the visual appearance of a long straight line of soldiers standing at attention. Pilings, on the other hand, get their name from the medieval city where they were first used, Piling, China, now known as Changzhou. Even as late as 1480 C.E. in Germany, pilings were still being driven by hand-operated machines. Thank goodness for steam engines and the Industrial Revolution!

The “soldier” portion of the name derives from the visual appearance of a long straight line of soldiers standing at attention. Pilings, on the other hand, get their name from the medieval city where they were first used, Piling, China, now known as Changzhou. Even as late as 1480 C.E. in Germany, pilings were still being driven by hand-operated machines. Thank goodness for steam engines and the Industrial Revolution!

Deep Excavations

The difference between building an engineering marvel like a 6-story tower in medieval China and a modern-day skyscraper is quite distinct. If we didn’t have extremely deep foundations, our cities would be low and sprawling, rather than big and concentrated. To attain such heights, we use a method called top-down construction utilizing I-beams as the primary support component.

I-beams are not universally used. Alternatives exist such as concrete piles (cast in place), hollow pipes dug, or simply vibrated, into the ground, or even caissons, of the sort, used to build the foundations for New York City’s bridges and tunnels. The winning advantage goes to I-beam construction with wood lagging because of both material cost and speed of development.

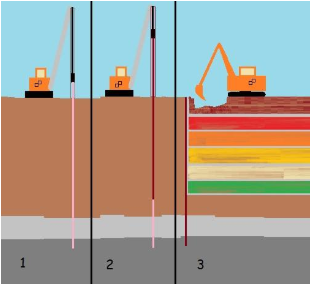

Soldier Pile walls make it possible to construct a deep excavation right next to a property line where topography, existing buildings, or infrastructure (say, a railway line or roadway) don’t permit further digging. Such a wall is created by drilling vertical holes (#1), from as little as six feet apart, to as much as 15, depending on soil conditions. I-beams are then placed vertically into the ground (#2) passing through disturbed bedrock (light grey) until they penetrate 1-1.6 meters into solid bedrock (dark grey). Excavation slowly reveals the I beams, layer-by-layer (#3), which gives a chance to install the lagging (often horizontal timbers) using the lips of the I-beam to keep them in place. As the lagging is installed, the void behind the wood is backfilled and compacted for strength and to minimize water penetration.

Now, of course, at any depth or exposed “height” greater than 15 feet (4.5 meters) the soil behind the lagging would put too much strain on a vertical I-beam and it would begin to bend. To prevent this, devices called wales are connected (blue circle) to two adjacent I-beams (yellow). The massive steel wale is then attached to a tie-back anchor (red circle) that penetrates well back into the soil, which then can offer a counterforce to keep the I-beams aligned. It is a wonderful, reliable system that renders all sorts of internal supports unnecessary so that construction can continue unimpeded. It may not always be wood lagging, of course. Sometimes it may be temporary, sometimes permanent, but under less hospitable conditions, the materials may need to be concrete sheets or even steel panels, but that will put the cost much higher, and increases the time factor.

Secant Piles

Soldier Pile Walls aren’t as useful when the excavation is well below the water table, so Secant Piles, or overlapping concrete piles, are preferred. They offer much greater water resistance.

![]()

For these, a shallow trench is prepared, and foam molds are placed inside. They are surrounded and reinforced with rebar, and then concrete is poured around them to secure the foam in place. The light grey holes are drilled first, and filled, often with softer, unreinforced concrete. After they have had a chance to set and gain strength, the dark grey holes are drilled; this takes part in the earlier concrete away (thus the word “secant”) from, the softer light grey piles.

As you can see, this forms a continuous solid wall. The light grey piles continue to cure, gaining strength, and the whole construction becomes very resilient. This sort of wall often requires internal support, but wales can be used here, too.

The Takeaway – Soldier Pile Walls

Whatever types of “support” your project may require, remember that your best choice is always the bright orange of Oscar Orduno, Inc.…

We are the experts you need!

We will always minimize unnecessary disruption to your neighbors, other tradespeople, and people in the vicinity. At Oscar Orduno Inc., we promise to keep everyone safe during the construction process and to operate in a manner to ensure the utmost protection for your structures and property. We pay attention to all the details, so when the job is done you can be confident that it was done right!

And here is our latest acquisition! This beauty is ideally suited to perform these installations with speed, efficiency, and no excessive noise! This is just one more reason that you want orange on your job site.

We cover most of the state, too, including Dallas, Fort Worth, Austin, San Antonio, Houston, Lubbock, Amarillo, Tyler, and Waco. You’ll see our bright orange equipment in almost all of those places, and many more besides! We’d love to hear you say “Howdy,” so take a moment and get in touch.

Read more about our Excavation Services here!